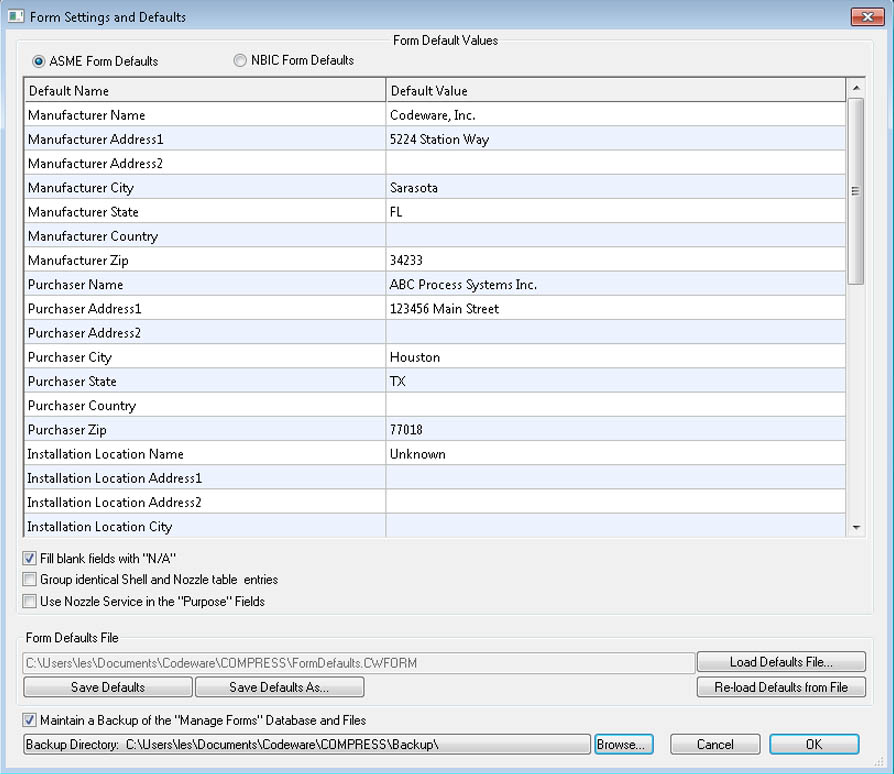

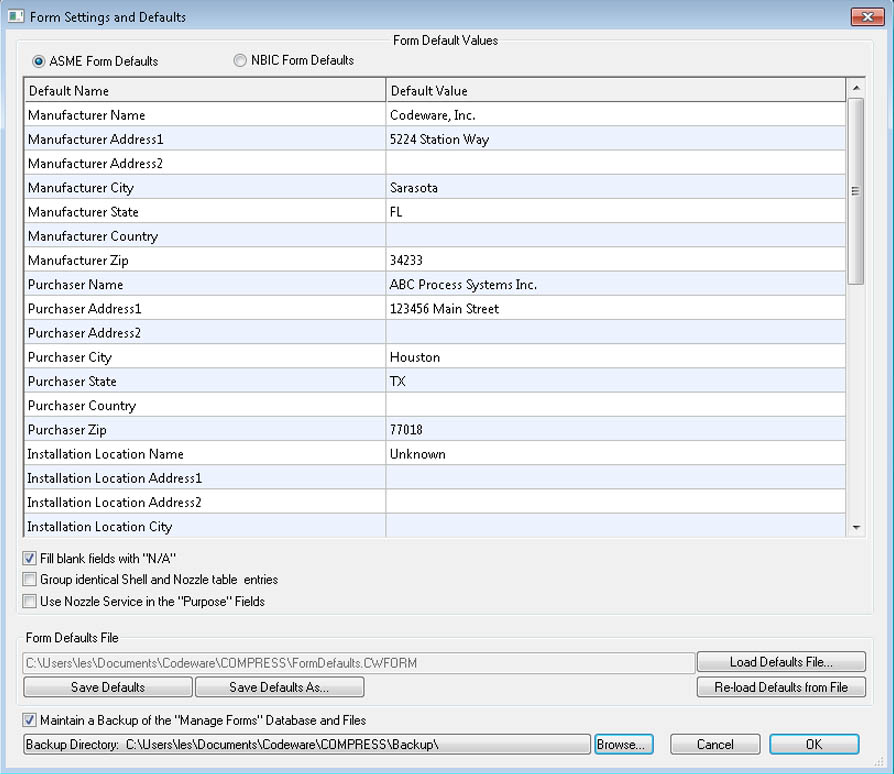

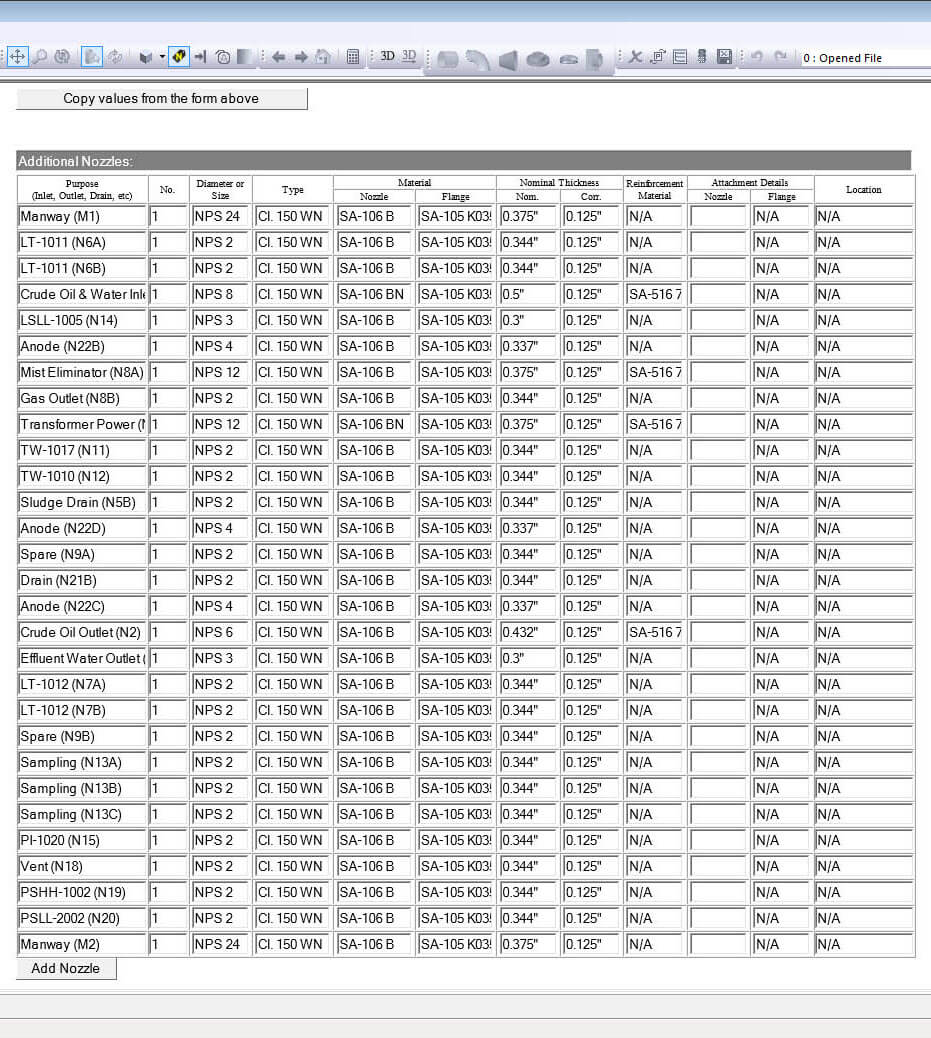

The COMPRESS Forms feature simplifies the creation, submission and management of ASME Manufacturer’s Data Reports and NBIC Repair and Alteration Forms. It’s not uncommon for vessels to have multiple shell courses, 35 or more nozzles and flanges all of which need to be properly documented. COMPRESS speeds up this error prone task by transferring design information from the COMPRESS model directly to the selected ASME form. Form defaults can be set up so that your company information only needs to be entered once. A convenient forms update check makes the latest form layouts available without having to wait for a general software update as well. Note that the COMPRESS Forms feature does not involve the use of a separate “module” or program like MS Excel as is the case with other software.

Manufacturer’s Partial Data Report Forms U-2 and U-2A (ASME rules require that these be attached to a U-1 or U-1A Form)

Manufacturer’s Certificate Of Compliance Form U-3A (for vessels subject to the size and inspection requirements of ASME VIII, U-1(j) to be stamped “UM”)

Manufacturer’s Data Report Supplementary Sheet Form U-4 (typically used for vessels with many nozzles)

Manufacturer’s Data Report Supplementary Sheet Form U-5 for shell-and-tube heat exchangers Manufacturer’s Data Report Form A-1 (as required by ASME VIII-2) Manufacturer’s Partial Data Report Form A-2 (as required by ASME VIII-2) National Board Inspection Code Report of Repair Form R-1 National Board Inspection Code Report of Alteration Form R-2COMPRESS includes forms management for archiving forms and supporting documentation. In addition, it can transmit your completed forms to the National Board electronically. This saves time and takes advantage of the National Board’s lower electronic filing fees.

Nozzles Simplify the detailing of nozzle attachments with flexible and intuitive nozzle design capabilities.

Nozzles Simplify the detailing of nozzle attachments with flexible and intuitive nozzle design capabilities.  Finite Element Analysis The heat exchanger option now includes built-in Finite Element Analysis (FEA) for TEMA Flanged and Flued Expansion joints.

Finite Element Analysis The heat exchanger option now includes built-in Finite Element Analysis (FEA) for TEMA Flanged and Flued Expansion joints.

Vacuum Rings Drag-and-drop vacuum rings and quickly see how the external pressure rating changes.

Vacuum Rings Drag-and-drop vacuum rings and quickly see how the external pressure rating changes.

Quick Design Speed up the process of pressure vessel modeling with Quick Design mode.

Quick Design Speed up the process of pressure vessel modeling with Quick Design mode.

Productivity Software packages like COMPRESS exist to increase productivity and save Engineering hours.

Productivity Software packages like COMPRESS exist to increase productivity and save Engineering hours.

Heat Exchanger Perform ASME UHX and TEMA calculations and transfer these designs to your estimating and drafting departments.

Heat Exchanger Perform ASME UHX and TEMA calculations and transfer these designs to your estimating and drafting departments.

Division II Many companies use the alternative rules of Division 2 because of the cost savings, versus Division 1.

Division II Many companies use the alternative rules of Division 2 because of the cost savings, versus Division 1.

MDMT Rules of UCS-66 The rules of UCS-66 guard against vessel failure by brittle fracture, a low probability high consequence event.

MDMT Rules of UCS-66 The rules of UCS-66 guard against vessel failure by brittle fracture, a low probability high consequence event.

External Pressure Design Simplify the complexity of

External Pressure Design Simplify the complexity of

UG-28 rules for external pressure of 15psig and greater.

Jacketed Vessels Design both conventional and half pipe jacketed vessels as a standard feature in COMPRESS.

Jacketed Vessels Design both conventional and half pipe jacketed vessels as a standard feature in COMPRESS.

Vessel Wizard The Vessel Wizard speeds pressure vessel design by creating complete pressure vessel models with minimal input.

Vessel Wizard The Vessel Wizard speeds pressure vessel design by creating complete pressure vessel models with minimal input.

COSTER Import files from COMPRESS and create user customizable pressure vessel cost estimates in spreadsheet format.

COSTER Import files from COMPRESS and create user customizable pressure vessel cost estimates in spreadsheet format.

Flange Design Create optimized Appendix 2/ASME B16.5/16.47 flange designs with minimal time and effort.

Flange Design Create optimized Appendix 2/ASME B16.5/16.47 flange designs with minimal time and effort.

Weld Seams Designers can visually confirm good practices such as staggered longitudinal seams.

Weld Seams Designers can visually confirm good practices such as staggered longitudinal seams.

Lifting & Rigging Use an accurate weight, the correct center of gravity, and apply the actual section properties.

Lifting & Rigging Use an accurate weight, the correct center of gravity, and apply the actual section properties.

Modeling + Drawings The Codeware Interface includes Drafter 3D, a feature that auto-generates 2D pressure vessel drawings.

Modeling + Drawings The Codeware Interface includes Drafter 3D, a feature that auto-generates 2D pressure vessel drawings.

True SOLIDWORKS Models Sketches, operations and drawings can be manipulated as if the model had been created manually in SOLIDWORKS.

True SOLIDWORKS Models Sketches, operations and drawings can be manipulated as if the model had been created manually in SOLIDWORKS.  Related Codes COMPRESS implements a wide range of related engineering methods, codes and standards.

Related Codes COMPRESS implements a wide range of related engineering methods, codes and standards.

Design Mode Save time by reducing the trial and error iterations that would otherwise be required when designing pressure vessels.

Design Mode Save time by reducing the trial and error iterations that would otherwise be required when designing pressure vessels.

Rating (Analysis) Mode The COMPRESS Rating Mode takes your design and determines the vessel’s MAWP, MAEP and MDMT.

Rating (Analysis) Mode The COMPRESS Rating Mode takes your design and determines the vessel’s MAWP, MAEP and MDMT.

Hydrotest Performing hydrotest stress calculations in the design stage prevents equipment damage during hydrotesting.

Hydrotest Performing hydrotest stress calculations in the design stage prevents equipment damage during hydrotesting.

Hillside Nozzle COMPRESS saves time by calculating chord openings and governing planes of reinforcement automatically.

Hillside Nozzle COMPRESS saves time by calculating chord openings and governing planes of reinforcement automatically.

ASME Editions Older ASME Codes are retained in all COMPRESS releases so you can always use the latest software.

ASME Editions Older ASME Codes are retained in all COMPRESS releases so you can always use the latest software.

Automatic Liquid Levels COMPRESS eliminates the need to manually calculate each vessel component’s liquid static head.

Automatic Liquid Levels COMPRESS eliminates the need to manually calculate each vessel component’s liquid static head.

Global External Loads The Loads Menu allows designers to easily consider global external loads when sizing pressure vessel supports.

Global External Loads The Loads Menu allows designers to easily consider global external loads when sizing pressure vessel supports.

Clips and Lugs Designers can quickly include the mechanical effects of pressure vessel internals and attachments in their designs.

Clips and Lugs Designers can quickly include the mechanical effects of pressure vessel internals and attachments in their designs.

Stacked Vessels Certain industrial processes require pressure vessels with multiple chambers operating under different design conditions.

Stacked Vessels Certain industrial processes require pressure vessels with multiple chambers operating under different design conditions.

Appendix 46 Produce more economical Div 1 pressure vessel designs with increased accuracy from the Div 2 design by rule equations.

Appendix 46 Produce more economical Div 1 pressure vessel designs with increased accuracy from the Div 2 design by rule equations.

Manufacturer's Data Reports Simplify the creation, submission and management of ASME Manufacturer’s Data Reports and NBIC Repair and Alteration Forms.

Manufacturer's Data Reports Simplify the creation, submission and management of ASME Manufacturer’s Data Reports and NBIC Repair and Alteration Forms.

Support Skirt Openings Specify piping connections to vertical vessels that require additional piping and openings cut out of the support skirt.

Support Skirt Openings Specify piping connections to vertical vessels that require additional piping and openings cut out of the support skirt.

Foundation Loads Summary Break down the loads for the specified vessel operating conditions including weight, wind, seismic, and vortex shedding.

Foundation Loads Summary Break down the loads for the specified vessel operating conditions including weight, wind, seismic, and vortex shedding.

Shipping Saddles

Shipping Saddles  COMPRESS provides a shipping saddle option based on the industry standard Zick Analysis.

COMPRESS provides a shipping saddle option based on the industry standard Zick Analysis.  UG-80 and UG-81 COMPRESS automatically provides out-of-roundness tolerances that must be maintained during pressure vessel fabrication.

UG-80 and UG-81 COMPRESS automatically provides out-of-roundness tolerances that must be maintained during pressure vessel fabrication.

Nameplate Design Every pressure vessel is required by Code to have a nameplate. COMPRESS handles this by including a convenient nameplate option.

Nameplate Design Every pressure vessel is required by Code to have a nameplate. COMPRESS handles this by including a convenient nameplate option.

Fatigue Screening Quickly enter fatigue data and make performing VIII-2 or Appendix 46 Fatigue Assessments simple.

Fatigue Screening Quickly enter fatigue data and make performing VIII-2 or Appendix 46 Fatigue Assessments simple.

WRC 537 Nozzle Loads Check stresses on nozzles using WRC 107 and WRC 537 stress analysis for spherical and cylindrical shells.

WRC 537 Nozzle Loads Check stresses on nozzles using WRC 107 and WRC 537 stress analysis for spherical and cylindrical shells.

![]()

Software packages like COMPRESS exist to increase productivity and save Engineering hours.

![]()

Perform ASME UHX and TEMA calculations and transfers these designs to your estimating and drafting departments.